It is fully mounted in the factory and supplied inclusive of customer-specific processing. The front plate is permanently connected with the enclosure body. The most economical version in the range. MultiPANEL Display with aluminium front plate. You receive the plate with or without processing. This is fastened to the frame with clamping pieces.

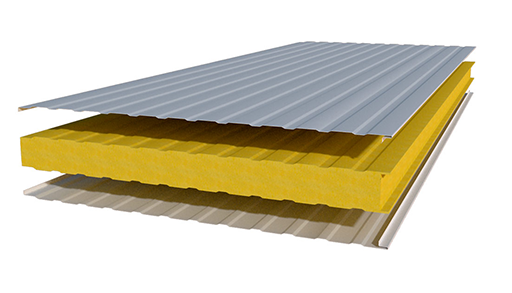

The enclosure frame is inset flush in a front plate. This is fastened to the frame with stays and clamping pieces. Las medidas que tiene el Multitecho son de de 1 hasta 6, mientras el calibre de las láminas que funcionan como caras del panel, pueden ser de 26/26 y 26/28. Fastening takes place with the aid of the fastening clips supplied by the manufacturer.Ī front panel is inset flush in the enclosure frame. Los dos son compuestos de la misma forma, con dos caras de acero pintro unidas con un núcleo de poliuretano, pero sus medidas son diferentes, para que se puedan adaptar a cada necesidad. Panel PCs, for example from Siemens, Beckhoff, etc., can be directly installed in the enclosure frame without additional accessories. MultiPANEL Kommando with aluminium front plate inset from the rear. El Multipanel es un sistema de construccin prefabricado, que se caracteriza por su estructura tipo sndwich, ya que se conforma por dos lminas de acero acanaladas pintro (Polister Estndar, Duraplus o Fluorocarbonada) con relieves o liso y vinil, unidas a un ncleo con espuma de poliuretano rgida expandido de alta densidad (40 kg / cerrada m3) que le brinda un gran capacidad. MultiPANEL Kommando with aluminium front plate inset from the front. MultiPANEL Kommando for the direct installation of a panel PC. Three enclosure depths of 70, 85 and 130mm offer the maximum in flexibility for every type of internal mounting MultiPANEL Kommando – the 22mm wide front plate enables the direct installation of panel PCs, a front plate, as well as a combination of the two.

#LAMINA DE MULTIPANEL FULL#

MultiPANEL Display – is almost borderless and facilitates the full surface installation of front plates or glass fronts, e.g. Thanks to the profile technology, multiPANEL can be produced in the customer's required width and height to the precise millimetre multiPANEL com-mand enclosures produced from aluminium profiles offer the combination of technical fi-nesse and maximum flexibility, in conjunction with a highly advanced and urban design for modern machines.

#LAMINA DE MULTIPANEL SKIN#

The method of claim 5 wherein the outer panel is a skin used on an exterior automotive part and the inner panel is a reinforcing member.Powder coating, RAL 9005 Deep black, fine structureīolted rear wall (only MPD 00 and MPK 00) Lock and hinge, blackĭesign is playing an increasingly significant role in machine construction. The method of claim 6 further comprising constructing said inner and outer panels of steel. The method of claim 5 further comprising forming a hem flange to create a flow channel substantially along the entire perimeter of both panels.

Thereafter, injecting an adhesive substance into the longitudinal flow channel through the inlet passageway and Placing the inner panel adjacent to the outer panel īending the edge of the outer panel around the edge of the inner panel to come in firm contact with the inner panel in order to create a sealed longitudinal flow channel and to align the hole over the notch thereby defining an inlet passageway into the flow channel Providing an outer panel with a hole near an edge thereof

Providing a second panel shorter in length in at least one direction than the first panel A method of securing two panels together to create a multi-panel device comprising the steps of:

0 kommentar(er)

0 kommentar(er)